Description

Meticulous engineering meets elegant design.

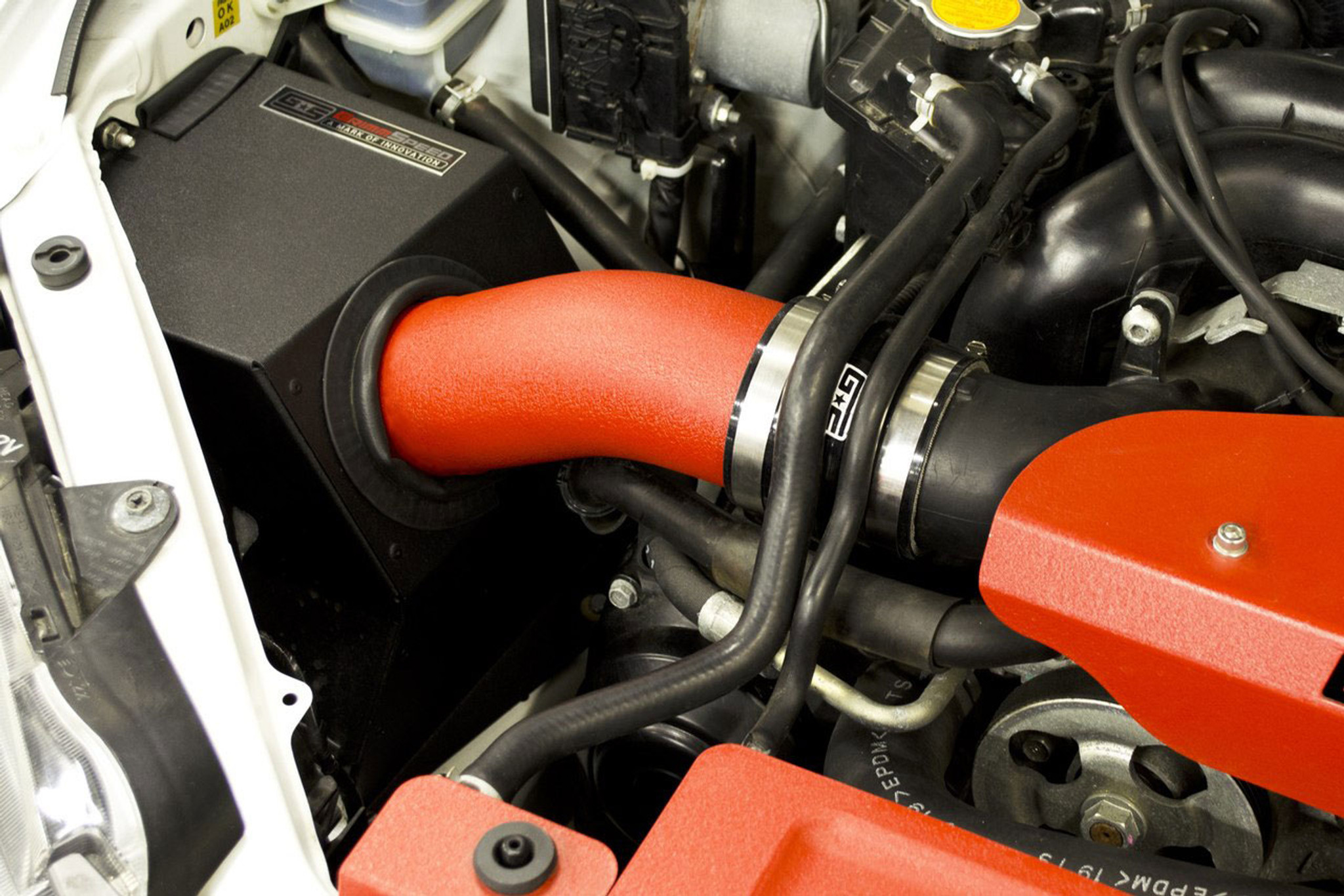

Based on our testing and research, design requirements for this intake became simple. The MAF sensor must be protected from the heat of the engine bay for more accurate readings. The filter must not be close enough to the ground such that water/hydrolocking are a concern. The MAF sensor must be placed relative to the filter and air straightener, similar to the OEM airbox, so that airflow readings are consistent and reliable. The intake tube must be no longer than necessary with minimum bend angle, to reduce restriction. The heatshield must provide sealing between the induction area and the hot engine bay to keep air intake temperatures low. The GrimmSpeed intake shown here achieves each of these requirements and more. What is accomplished is a true hybrid of traditional Cold Air Intakes and Short Ram Intakes, with all the advantages and none of the compromises.

Quick Specs

- Hybrid Cold Air/Short Ram Design – Combining the advantages and eliminating the negatives of both traditional intake designs

- Air straightener – Dimensionally mimics the factory configuration for accurate MAF sensor readings

- MAF sensor location – Inside heat shield, isolated from engine bay heat

- Custom reusable high flow air filter – Integrated velocity stack entrance smooths incoming air

- Made in the USA – Right here in Minnesota, in fact

- 30min Installation – Extremely simple with our written and video guides