Description

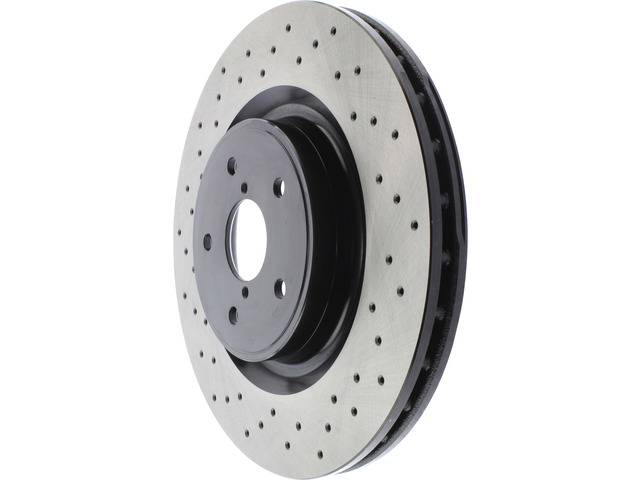

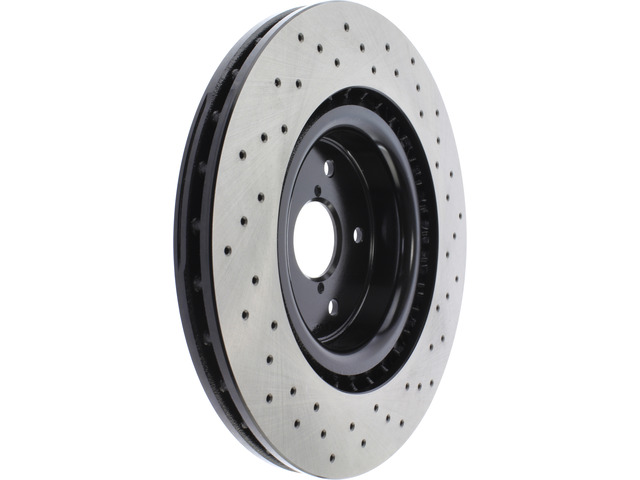

Centric Premium™ brake rotors are built to original equipment specifications, using production processes, and are manufactured to meet QS and ISO Quality System Standards.

Centric premium rotors utilize an Electrocoating finish that provides long lasting corrosion protection. E-coating is a superior electro-statically applied finish designed to withstand 400 hours of salt water exposure without rusting. Phosphate finishes utilized by other manufacturers provide only minimal protection from the elements; these finishes are generally only effective for the shipping and storage portion of a rotor’s life. The addition of heat and moisture eliminates the effectiveness of phosphate finishes resulting in immediate corrosion once installed in the vehicle.

Features

- Painted hat and outer edge for corrosion resistance

- Optimal surface finish for consistent stopping feel from the first stop

- Advanced metallurgy for optimal heat transfer and structural strength

- OE vane design and plate thickness for heat capacity and strength

- Low initial lateral run-out and disc thickness variation for smooth, vibration free stopping

- Precision balance for vibration free performance