I think every time I scroll through Facebook, I see posts asking “is this level of knock, ok?” or “my car just picked up -2.8deg knock, what do I do now?”. Queue the part out memes. While knock can be harmful to an engine, most knock detected by your Accessport is likely false knock. Knock, also called detonation, is when a small pocket of the air/fuel mix ignites outside of the flame front that was ignited by the spark plug. The shockwave created by this abnormal ignition creates rapid spikes of pressure in the cylinder and can cause damage if left untreated. The knock sensor is simply a microphone that is bolted to the cylinder block. The rapid spikes of cylinder pressure are what the knock sensor picks up and determines a knock event happened, the ECU then quickly makes the needed adjustments to ignition timing to try and stabilize the combustion.

Knock Knock – What is Engine Knock and How to Monitor it

While real knock can quickly cause damage to your engine, most of the knock you see on your Accessport is usually false knock. Lots of things can cause false knock such as: accelerating from a stop, hard shifting, using launch control, a worn engine mount, AC compressor turning on, or even just a bolt bouncing around on the engine block. Today’s engines are built and designed to be as fuel efficient as possible. To do this, the engine manufacturers have to push the engine to the edge of knock to gain every inch of efficiency possible. The knock sensor enables them to get that efficiency without causing harmful damage that could cause premature wear of the engine. If you were to hook up your Accessport and watch the stock tune on a 2015+ WRX, you would be amazed at just how much knock is picked up and how much the DAM moves around. Subaru seems to have gone on the side of caution with just how sensitive the knock system is.

Monitoring knock is a great thing to do with your Accessport. On all Subaru models except the 2015+ WRX DIT, more details below, determining which knock readings are actual knock and false knock will give you a better idea of your engine’s health and if anything needs to be addressed. Subaru employs several methods to help control knock. The first method the ECU can use is Feedback Knock or “FBK”. If the ECU perceives knock events it can instantaneously pull ignition timing with Feedback Knock. The second method is Fine Knock Learned or “FKL”. If the ECU sees enough knock over the same load and rpm area and keeps pulling ignition timing with Feedback Knock it can use Fine Knock Learned to proactively pull timing at those rpm and load areas until the ECU stops hearing knock. The last method is the DAM or “Dynamic Advance Multiplier”. On the 2002-2005 WRX the DAM can range from 0-16, 16 being optimal. On all of the other Subaru models the DAM can range from 0-1, 1 being optimal. If the ECU perceives knock events it can drop the DAM to globally pull ignition timing. The only way to get the DAM back to optimal of 16 or 1 and Fine Knock Learned to 0, is with an ECU reset or to drive in the load and rpm area that is causing the DAM to drop or Fine Knock Learned. An example is, if you are getting Fine Knock Learned of -1.4 at 3200rpm and 5psi of boost, simply avoiding that spot won’t cause the FKL to go away. The ECU needs to go through that spot and hear there is no knock happening. Only then will it move the FKL back to 0.

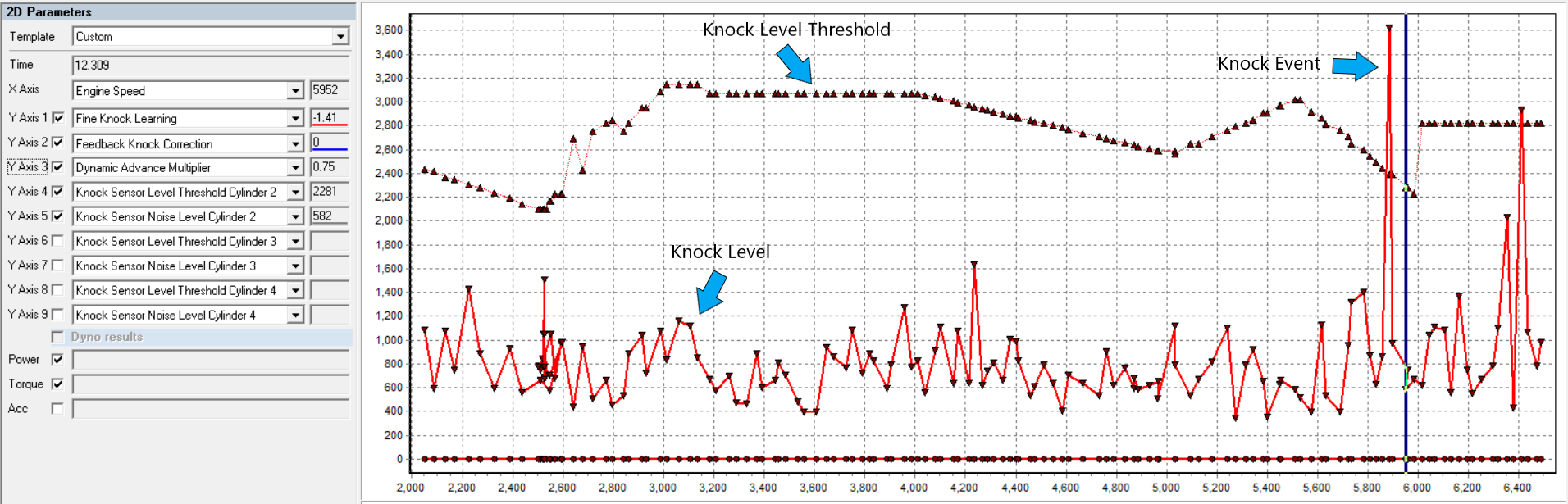

Above is a log from a stock 2020 WRX. The top line, ranging from 2000-3200 is the knock sensor threshold. The middle line is the actual knock level being reported from the knock sensor. You can see that at just before 6000rpm the knock level jumps to 3800, while the threshold level is 2600. The ECU sees a knock event happening here and pulls -1.41deg ignition timing. You can also see the DAM is at .75, It started at .6875 and after a few pulls worked its way up to .75 and stayed there during the testing.

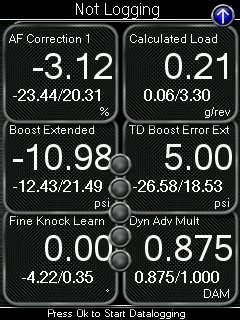

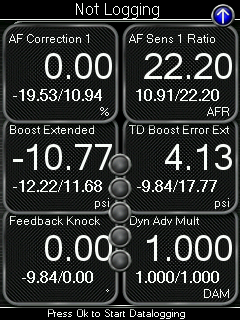

The 2015+ WRX uses all these strategies as well but can use any of the strategies at any time to address perceived knock. In other words, the 2015+ WRX can drop DAM or use Feedback and Fine Knock Learned in any order to reduce ignition timing. One thing to note about the 2015+ WRX is the knock strategy is much more sensitive than the EJ cars. Some of the models that come with the FA engine can run on 87oct and is likely why Subaru employed the DAM to be more sensitive, so if you pump a lower grade fuel the ECU can quickly figure that out and make the proper adjustments to ignition timing globally. It is somewhat normal for the DAM to drop on these cars and if it does it doesn’t necessarily mean there is a problem. In fact, on the stock tune the DAM starts at .6875 every time you start the car and works its way to 1 if you have good fuel, so just because your DAM isn’t at 1 doesn’t mean you have major problems. The only way to get the DAM backup is either an ECU reflash or to drive in the load and rpm area that caused the DAM to drop. If you reflash the ECU and the DAM drops again that may be cause to look into what caused the DAM to drop.

Lastly when monitoring knock just knowing the peak values doesn’t give you the whole story. Looking at your Accessport and seeing that -2.8deg on FBK gauge peak value doesn’t mean much. You need to actually see when that -2.8 happens to help determine if it was false knock or something that needs to be addressed.

Below are knock numbers you would expect to see on a good running engine/tune. If you are seeing higher negative numbers, it might be a good idea to investigate and see if it’s false knock or something that needs to be corrected in the tune. Reaching out to your tuner is always a good idea if you have any questions regarding knock.

DAM

- 2002-2005 WRX- 16

- 2015+ WRX – .6785-1

- All other Subaru models – 1

Feedback Knock

- Up to -2.8 while cruising

- -1.4 under full throttle. It is normal to see some knock corrections under full throttle, if it is constantly happening, higher than -1.4, and for long periods it might be a good idea to look into it.

Fine Knock Learned

- Up to -2.8 while cruising

- -1.4 under full throttle. It is normal to see some knock corrections under full throttle, if it is constantly happening, higher than -1.4, and for long periods it might be a good idea to look into it.

Below is a list of things that can potentially cause high knock numbers and can typically be considered false knock. Just because you are seeing false knock does not mean you shouldn’t investigate and fix the issue. Some things listed just happen and can be avoided, false knock from the exhaust rattling or a loose knock sensor should definitely be repaired to stop the knock.

- Launch Control– Any time you are launch control you can pick up feedback / fine knock learned corrections along with the DAM dropping. This is normal from the engine bouncing on the rev limiter and also aggressively releasing the clutch / drivetrain shock from launching.

- Flat Foot Shifting/Aggressive Shifting– With its aggressive nature of rapidly releasing the clutch, the drivetrain shock can definitely cause high knock numbers along with dropping the DAM. Even if you are not flat foot shifting, but shifting fast you can pick up high knock numbers.

- Mashing the throttle– Rapidly pressing the throttle to wide open can cause false knock events.

- Starting from a dead stop, clutching out

- AC Compressor turning on– Most common on the 2015+ WRX, you can log the AC compressor turning on and see Feedback or Fine Knock Learned when it turns on.

- Loose exhaust- Everything from loose heat shields to the downpipe not being bolted to the trans hanger and hitting it.

- Loose knock sensor- We have seen this a time or two after someone had their “mechanic” friend do some work or build their engine.

- Anything that is mounted to the engine but is not properly torqued down.

- Accelerating at a low rpm/ high gear- cruising in 5th/6thgear and getting into some good boost can cause false knock. Although it might be false knock it’s not good practice to put high loads on the engine when rpms are low and in top gear. Just like an automatic would do, downshifting to pass is much better on everything.

- Broken Ringlands- As surprising as it sounds, I have had cars that were picking up to -11deg knock while cruising or accelerating lightly. A compression test confirmed bad ringlands. This isn’t super common but I have seen it.